Advancements in Fiber Optic Splice Dome Closures

Fiber optic networks form the backbone of modern communication systems, carrying vast amounts of data over long distances. A critical component in these networks are splice closures, which house and protect the splices between individual fiber strands. Traditional splice closures come in various shapes and sizes, but one increasingly popular form factor is the dome closure.

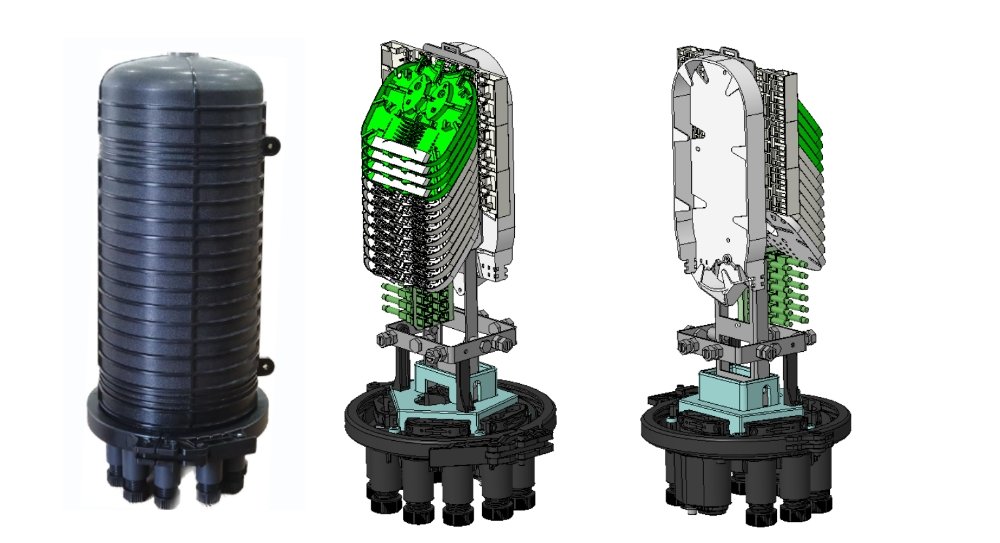

Fiber optic dome closures provide a protective water and gas tight enclosure to house splices and optical splitters or couplers, allowing flexible network reconfiguration without exposing the delicate internal components. Unlike previous rigid cassette-based closures, domes allow for feeder and distribution cables to enter and exit at any angle, facilitating easier network expansions. Recent advances have further improved dome closure design for handling high fiber counts and density.

One major innovation is the development of high capacity splice trays and organizers that can accommodate up to 144 fiber splices each in a compact footprint. These trays utilize features like micro-grooves and color-coded splice retainers to orderly arrange individual fiber strands for identification and access. By employing flexible routing clips and hinged retainers, the splice trays also facilitate rapid splice loading while maintaining fiber bend radius to prevent signal loss.

Modular dome architectures allow splice capacity to scale on demand. Additional splice trays can be installed in the base of the dome as needed without expanding the external dimensions. This ensures unused space in dome closure installations is minimized to optimize carrying capacity per foot of buried conduit. Some advanced modular domes allow capacity growth from a few dozen fibers up to 1344 strands.

Sealing performance is critical for dome closure durability. Recent designs now employ fully potted cable entry ports using heat-cured epoxy, providing a completely waterblocked peripherary seal even in harsh environments. The latest compound materials withstand temperatures from -40°C to over 85°C while resisting chemical corrosion. Far exceeding industry requirements, these encapsulant systems prevent moisture intrusion over decades.

Split dome constructions with removable lids improve access for maintenance and upgrades. Snap-fit locking ratchets allow simple re-entry while maintaining precise alignment and a tight seal across the dome perimeter gasket. Anti-snag closing prevent fibers and internal components from being pinched or damaged when replacing lids. Support racks firmly secure the splice trays and prevent shifting during enclosure reassembly.

In summary, fiber optic splice dome closures are undergoing rapid innovation to meet the demands of high-capacity modern optical networks. Advances in modular splice tray density, sealing performance, and re-entry designs now enable flexible fiber management scalable from small access sites up to massive backbone nodes. The improved protectiveness and craft-friendly access of dome enclosures will support the growth of communication systems far into the future.

Product Recommendation: FiberMints Fiber Optic Splice Dome Closures

In the dynamic landscape of fiber optic technology, choosing the right splice closure is crucial for ensuring the longevity and efficiency of communication networks. FiberMints stands out as a reliable and innovative provider in this space, offering state-of-the-art Fiber Optic Splice Dome Closures designed to meet the evolving demands of modern optical networks.

Key Features:

High Capacity Splice Trays: FiberMints' dome closures feature cutting-edge splice trays capable of accommodating up to 144 fiber splices each, optimizing space utilization while maintaining organized fiber management.

Modular Architecture: The modular design allows seamless scalability of splice capacity. Users can easily add additional splice trays without expanding the external dimensions of the dome, providing a flexible solution that grows with network requirements.

Advanced Sealing Performance: The dome closures employ fully potted cable entry ports with heat-cured epoxy, ensuring a water-tight seal even in harsh environments. The compound materials used withstand a wide range of temperatures and resist chemical corrosion, exceeding industry standards for long-term durability.

Split Dome Construction: FiberMints' split dome constructions with removable lids enhance accessibility for maintenance and upgrades. The snap-fit locking ratchets enable simple re-entry while maintaining precise alignment and a tight seal, preventing moisture intrusion and ensuring the protection of internal components.

Craft-Friendly Access: Anti-snag closing features prevent damage to fibers and internal components during lid replacement. Support racks firmly secure splice trays, preventing shifting during enclosure reassembly, ensuring a user-friendly experience for technicians.

Product Link: FiberMints Fiber Optic Splice Dome Closure

For those seeking a reliable and future-proof solution for fiber optic splice closures, FiberMints' offerings combine cutting-edge technology with practical design features. Explore their product line to discover how these dome closures can contribute to the efficiency, scalability, and durability of your communication network infrastructure.

Next Post:Basics and Selection Guide for Fiber Optic Connectors

Get a quote

Get a quote